How Flying Probe Testing Helps Improve PCB Reliability?

How Flying Probe Testing Helps Improve PCB Reliability?

Printed circuit boards (PCBs) are integral components of several electronics devices used today. The functionality of these devices relies heavily on PCBs, which is why they are subjected to rigorous testing at each step of manufacturing and assembly. Flying probe testing is one of the popular and widely utilized PCB testing techniques performed to ensure the performance of PCBs. Are you intrigued to know more about this PCB testing technique? If that sounds yes, then read this post till the end.

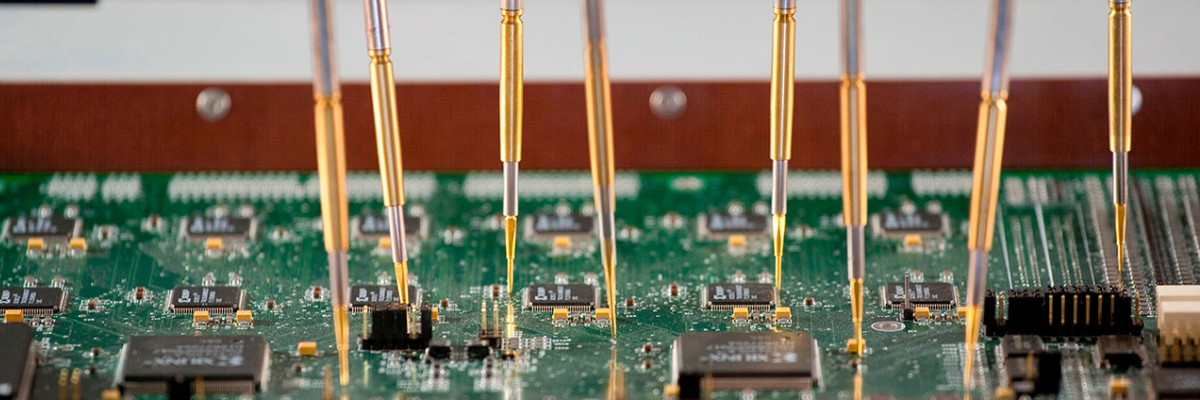

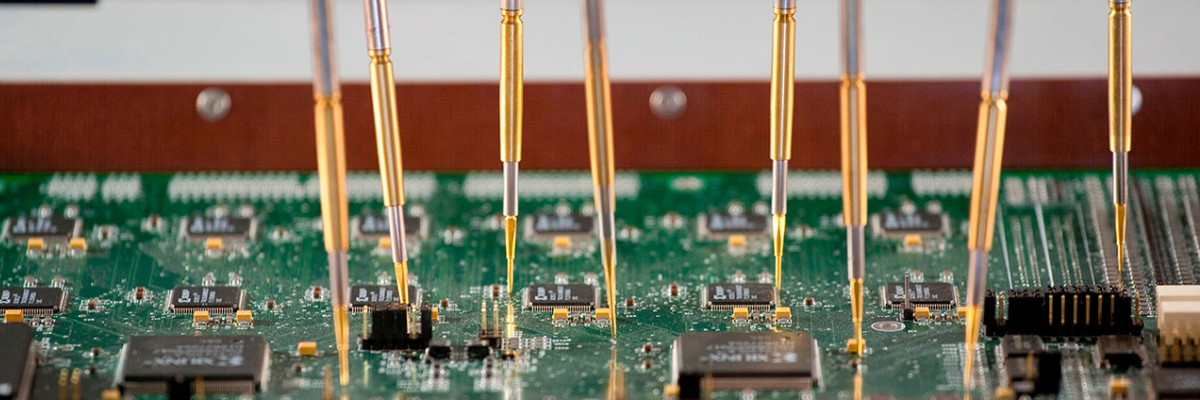

A Quick Introduction of Flying Probe Testing

Flying probe testing is a type of in-circuit testing. Unlike the regular in-circuit testing (ICT) that uses a beds-of-nail fixture, this PCB testing technique uses small movable pitches to establish contact with SMD pins and a camera for inspection of components and their polarity, open wires, etc. FPT can handle power-up testing simply by injecting signals at specified points on the circuit board while detecting the output at some other end. This technique does not require custom fixtures and thus is called fixtureless testing. FPT is ideal for low volume production and is more cost-effective compared to other PCB testing techniques owing to its ease of programming.

Benefits of Flying Probe Testing

Flying probe testing has gained immense popularity among PCB manufacturers because of its cost-effectiveness, accuracy, and other beneficial features. It has access to components better than most conventional methods. The following are some important ones.

-

The tests are programmed and controlled with the help of software, and hence it offers the flexibility to change component positioning or wiring if any issue is detected. The needle-like probes move seamlessly since there are no fixtures. Also, there are no testing points required, which makes it flexible.

-

In this method, the probes move as per the software program to connect with the specific nodes. Thus, no specific fixture is required. It possesses a simple mechanism to hold the PCBs in place. The landing position of the probing tool can also be set or changed rapidly as required.

-

This testing happens on a conveyor belt once the pre-programmed testing probe moves over the assembly in a specified manner. The loaded program is executed, and if it detects a fault or finds something that does not match the design requirements fed to the loader, it will return the output as failed.

-

Due to the clarity that flying probe testing assures, it is the most reliable testing method available today for some specific low-volume applications. This method is applied for both, checking blank boards and assemblies. This technique was developed primarily to test blank circuit boards; however, it is now used to test even complex assemblies.

-

As a probing tool, this is sensitive and hence identifies the smallest or hidden issues easily. Also, it has some advanced features and functionalities, such as the Phasor Measurement Unit (PMU), which determines the phase angle of voltage and other features that are usually checked in isolation testing. Since, this process is automated, it saves time and the possibility of human errors.

-

This method enables the testing of field-programmable gate arrays (FPGA), which are difficult to verify with other testing methods. It is widely used for prototypes of nanotechnology applications and complex, miniature electronic devices.

Precision and accuracy are the crucial aspects of PCB manufacturing and assembly. The better the circuit board quality, the better the application will perform. Hence, it is important to check these aspects in PCBs and validate the same via various testing and inspection methods. Being one of the experienced and reputed industrial players, Twisted Traces provides PCB manufacturing, assembly, and testing services and has worked with clients from diverse industries. The company offers the entire gamut of PCB testing and inspection services. This ensures the circuit boards are made of the finest quality and will meet the requirements of several challenging applications.