Understanding the Major Cost Factors in Multilayer PCB Assembly

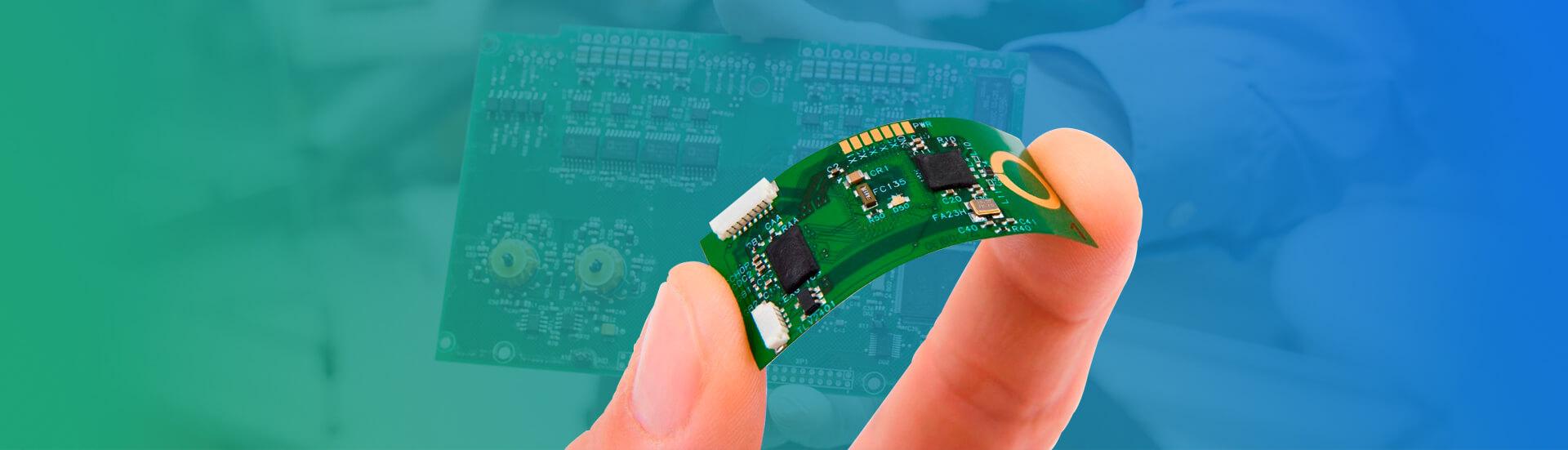

Multilayer Printed Circuit Boards (PCBs) are used in today’s sophisticated electronic devices. Known for their increased functionality, higher circuit density, and superior performance, these boards are the go-to choice for advanced technological applications. However, due to their intricate design, the assembly costs for multilayer PCBs can be significantly higher than their simpler counterparts. Understanding the main cost drivers is critical for managing expenses effectively. This post explores the key factors that majorly impact the pricing of multilayer PCB assembly.