Why PCB Assembly Rework is Necessary

Why PCB Assembly Rework is Necessary

Single printed circuit boards are simply blank boards which need to be assembled for their functioning. A PCB assembly is said to be ready when the boards are layered with components mounted, and all the wires in place with functional circuit. Such a PCBA is installed inside a device to make it functional. These PCBAs may need rework at times for various reasons, such as new versions or upgrades in the product, fixing a bug, adding new features, and so on. PCB assembly rework requires skill and expertise and needs to be done carefully to prevent damage to components, wires, and so on. This post explores the reasons why PCB assembly rework is generally done, required skillsets, and more.

Reasons for PCB Assembly Rework

Nowadays, there is a huge demand for RoHS-compliant or lead-free PCBAs, which are more challenging to repair and rework compared to lead-based boards. Skilled engineers are required to do this job. Here are some reasons why PCBAs may have to be reworked upon.

-

Developing new versions: Often, clients of PCBA service providers, such as OEMs of electronic or automotive equipment, develop new versions of their products. This is where advancement or feature addition in PCBAs is required. Also, innovative PCBA service providers develop their own versions of existing PCBs and sell it as a custom product.

-

Component addition or removal: At times, new components need to be added or some need to be removed from the board. This may be either due to some error or bug in functioning or a newly generated requirement. Creating a prototype of the existing PCBA could also be another reason.

-

Circuit tracing: Rerouting of circuit traces or wires may be required at times to establish new electrical connections. This may also be done as a part of repairs. This is done with specially designed tools and may involve the use of jumper wires or conductive ink depending on the requirement.

-

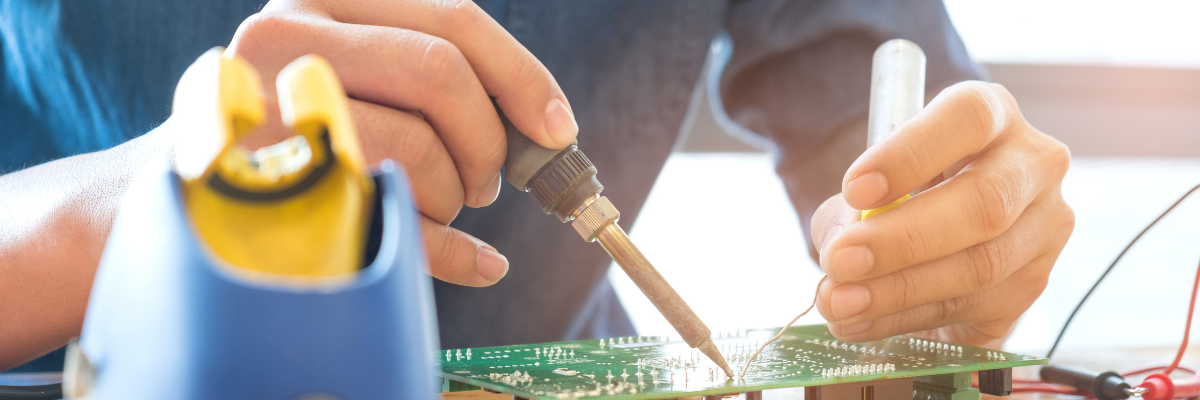

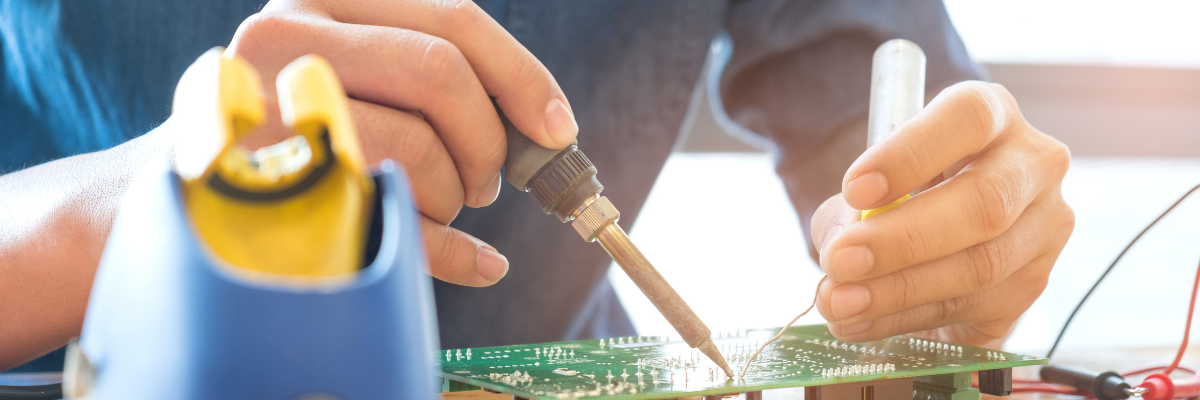

Soldering: Soldering and desoldering is done when mounting or removing components. This is done using soldering reflow techniques which help ensure the bonds are formed well. This needs to be done by a skilled engineer because it involves heating and cooling of board surfaces to create strong integrated joints.

-

Testing and inspection: This is crucial part of the PCB manufacturing and assembling phases, and is done at each step. Testing techniques may have to be repeated in case there are reworks or repairs in the PCBA to ensure it is functioning normally after the process is completed. This may involve automated optical inspection (AOI), functional testing, x-ray inspection, and so on along with a normal visual inspection.

Important Skills and Requirements an Engineer Must Have for PCB Assembly Rework

As mentioned, this job needs to be done carefully and requires the engineer to be skilled and focused. Here are some pointers in this regard.

-

The person must be calm and focused as this job requires total concentration even if you use automated tools.

-

They must have a good hand-eye coordination and attention to detail.

-

The engineer must have thorough knowledge of electronics in terms of electronic components, pin configurations, and identification codes among other aspects. They should also have an in-depth understanding of the concerned PCB design and layout and the exact requirement.

-

They must be proficient in using soldering tools such as hot air iron and reflow techniques.

-

They must also be experts in troubleshooting, PCB design, circuit tracing and routing, identifying faults in wiring, signal, and so on.

-

They must also know rework techniques such as surface mount device (SMD) removal and reflow, through-hole component removal, circuit trace modification, and jumper wire installation, and testing and inspection techniques as well.

Whether you are an OEM or a PCB manufacturer that develops new versions of existing assemblies, you may have to rework on PCBs at some point in time. As an OEM, it is recommended to partner with a reliable PCBA services provider for your PCB assembly rework. Ensure you partner with an experienced and credible PCB manufacturer and assembler as reworking requires specific skill in terms of removing any shields or coats above the components and reassembling is another daunting task. Twisted Traces is a known name in this segment, and offers custom options, end-to-end manufacturing and assembling services as well as PCB assembly reworks. The company uses advanced processes, materials, and fabrication techniques for PCB assembling as well as rework.

.png)

.png)