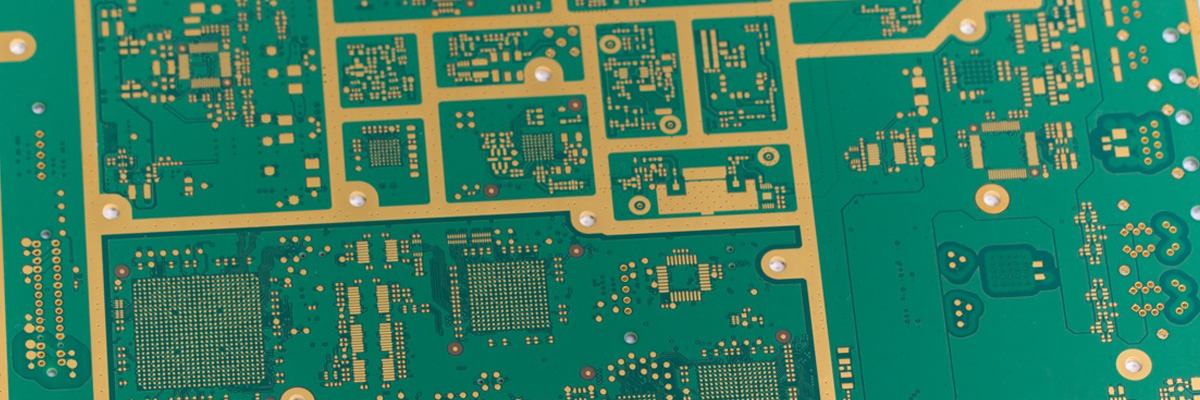

A printed circuit board is an essential element of many electronic devices because they add to its performance. Hence, manufacturers understand the importance of maintaining the quality of PCBs through various phases of manufacturing. Most manufacturers adhere to IPC standards for PCB manufacturing. These standards help them maintain the quality of PCBs from the design to testing and inspection phases. What is IPC? What are the popular IPC Standards? Stay tuned to know more.

IPC is a trade organization that standardizes the production and assembly requirements of printed circuit boards. Established in 1957, this organization was known as the Institute of Printed Circuit Boards and the Institute for Interconnecting and Packaging Electronic Circuits. The organization is now officially known as IPC since 1999. The organization publishes the acceptability standards for the printed circuit board industry. These standards are accepted throughout the globe. Currently, there are more than 4800 members in IPC. These members include companies that specialize in every aspect of PCB manufacturing right from designers to material suppliers to board manufacturers, assembly services, and OEMs.

Before going into the details of IPC standards for PCB manufacturing, it is important to understand these three classes:

The design rules differ across these classes, so manufacturers must take into consideration when taking up projects fitting into any of these classes. IPC6012 and IPC-A- 600 are two prominent IPC standards for PCB manufacturing covering inspection and performance of PCBs. Every manufacturer must refer or adhere to them during the PCB manufacturing and assembly. These standards are discussed in detail in the next section.

This specification is also referred to as IPC-600, which sets the level of acceptance criteria for each product class. The specification outlines the target, and acceptable and non-acceptable conditions for every product. These conditions may be found during internal or external observation. This specification focuses on visual interpretation of requirements set forth in various PCB specifications.

This specification outlines the performance requirements and qualification of rigid printed circuit boards in detail. Rigid circuit boards are designed in various ways such as single-sided PCBs, active/passive embedded PCBs, metal core PCBs, HDIs, and more. All these designs and their performance requirements are broadly classified in this standard.

Adherence to these standards will help PCB manufacturers benefit in the following ways:

As the benefits and key IPC standards for PCB manufacturing are well introduced here, it is now important that you partner with the right PCB manufacturer for your next project. This post ends by introducing you to Twisted Traces, a leading manufacturer of rigid, flex, and rigid-flex circuit boards for industries such as aerospace and satellite, medical, LED, military, consumer electronics, telecommunications, and automotive industries. The company follows various IPC standards for PCB manufacturing during all phases of manufacturing.