Design Considerations for PCB Stackups

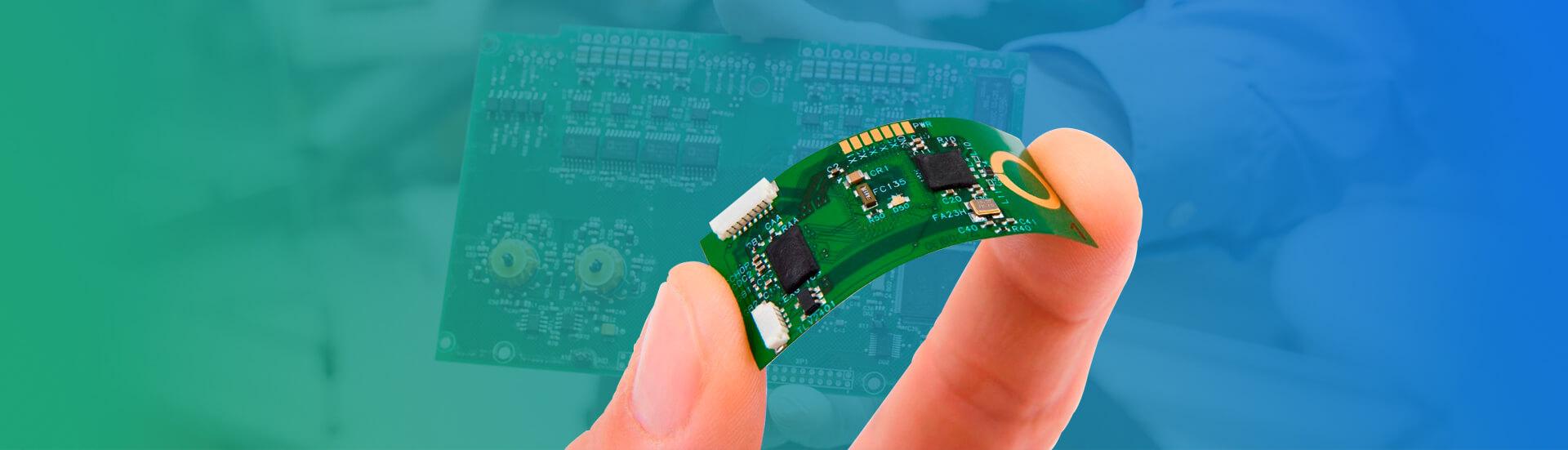

A stackup is an arrangement of PCB layers of conductors and dielectric materials, which enables the incorporation of multiple boards compactly within a device. This mostly includes the substrate, such as polyimide by upper and lower layers of copper, followed by adhesive and cover layers on both sides.